Failure Analysis in PB Networks

Oct 11th 2019

1. Location of the problematic segment / area

The PROFIBUS-INspektor NT can be installed by using an APKA II at any point of the network while running production. It continuously monitors the PROFIBUS communication and detects any logical problems. The passive data logger PROFIBUS-INspektor NT informs about:

✓ Error telegrams

✓ Telegram repetitions

✓ Device diagnostic

✓ Device Failure

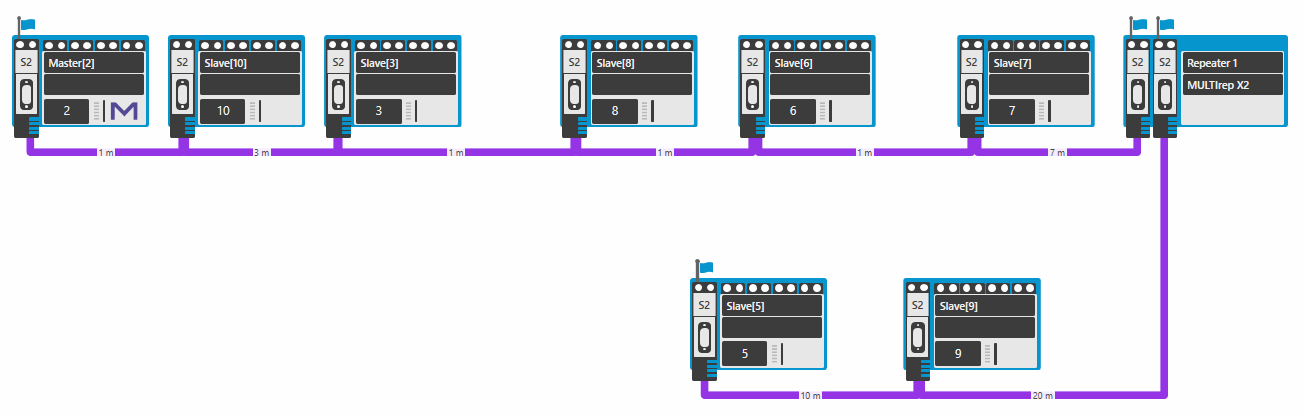

Due to information about device failure the problematic segment can be defined. For further measurements, you have to measure the network at the beginning and the end of every segment. These measurement points are highlighted (flags).

2. Logical and physical analysis of a segment

The PB-Qone is a multifunctional device for online or offline physical and logical quality diagnosis within seconds featuring:

✓ Physical analysis of PROFIBUS signal (signal shape, voltage level difference, oscilloscope).

✓ Easy comprehensible visualization of the signal quality values as bar chart for each device in the network.

✓ Fully automatic, non-responsible topology scan for the verification of the network structure.

✓ Detail information for each device including Traffic-light principle for evaluating the device status.

Due to the information about signal quality, you can determine if the failure has physical or logical reasons. If the signal quality shows low values, it has to be a physical problem. The reasons for logical failures are shown in the PB-Qone.

3. Physical analysis with the PROFtest XL II

The PROFtest XL is able to detect any physical problems in a PROFIBUS network. Therefore the customer has to measure on the two measurement points of the segment. As a result, the following parameters are shown:

✓ real cable length, cable impedance, and Baud rate scan

✓ Identification of cable faults (Line & Shield interruption, short circuit, correct termination)

Due to their superior diagnostic features, the InduSol PROFIBUS diagnostic & monitoring products are the perfect tools for not only commissioning but also troubleshooting, regular service and acceptance test.

It can be used as an early warning system on the basis of the functionality of the installed solution, are not being logged. As a result, the INspektors are only used for support in troubleshooting. The result is unnecessary and costly downtimes.

InduSol infrastructure components

The bus physics of PROFIBUS requires to perform the physical measurement at beginning and end of each network segment. For this reason all channels of the PROFIBUS repeaters of the MULTIrep family can be used as a measuring site for the corresponding segment using the PG interface at the sub-D plug. In addition, the MULTIrep hubs are the basis for stable star network structure due to up to seven galvanically isolated segments. The benefit, problems of one segment do not influence the other segments and the diagnostic LED allows easy identification of the affected segment.

For networks without an available PG interface at the beginning and/or end of a segment, the PBMA II can be used to create a permanent measurement point.