Failure Analysis in PROFIBUS Networks

Oct 11th 2019

How to Diagnose PROFIBUS Network Problems

Editor's Note: Originally published October 2019. Updated December 2025 with enhanced diagnostic workflows and current product specifications.

When PROFIBUS networks experience failures, identifying the root cause quickly is critical to minimizing downtime. PROFIBUS networks can fail for two primary reasons: logical communication errors or physical signal degradation. Logical failures involve issues with data transmission, telegram errors, and device communication. Physical failures stem from cable problems, impedance mismatches, EMC interference, or signal quality issues.

Efficient troubleshooting requires a systematic approach that isolates the problem area, determines whether the issue is logical or physical, and then applies the appropriate diagnostic tools. According to PROFIBUS standards and guidelines from PI, proper measurement and diagnostic procedures are essential for network reliability.

Locating the Problem Segment

Using the PROFIBUS-INspektor® NT to Isolate Problem Areas

The first challenge in PROFIBUS failure analysis is locating which segment or device is causing the problem. The PROFIBUS-INspektor® NT serves as an early warning system by continuously monitoring your network during production.

This passive data logger can be installed at any network point using an APKA II active programming cable without disrupting operations. It detects and logs critical network events including:

✓ Error telegrams (corrupted data transmissions)

✓ Telegram repetitions (retransmission attempts)

✓ Device diagnostics (status information from connected devices)

✓ Device failures (complete communication loss)

When the INspektor® NT identifies a device failure or recurring errors, you can pinpoint the problematic segment through its topology mapping. The device stores this information with timestamps, allowing you to see patterns and identify which segment requires further investigation. Once you've identified the suspect segment, the next step is measuring at the beginning and end of that segment, as indicated by the measurement point flags in the topology diagram.

Analyzing Signal Quality and Communication

Physical and Logical Network Diagnosis with the PB-Q ONE

After isolating the problem segment, the PB-Q ONE provides comprehensive analysis of both physical signal quality and logical communication parameters. This multifunctional tester works online or offline, delivering results within seconds.

The PB-Q ONE provides four critical diagnostic functions:

✓ Physical signal analysis including signal shape, voltage level differences, and oscilloscope views

✓ Signal quality visualization displayed as bar charts for each network device

✓ Fully automatic topology scan that verifies network structure without disrupting operations

✓ Detailed device information with traffic-light status indicators for quick evaluation

Determining Failure Type: Physical vs. Logical

The PB-Q ONE's signal quality measurements help you determine whether failures have physical or logical causes. Low signal quality values indicate physical problems such as cable damage, improper termination, or EMC interference. When signal quality is acceptable but communication errors persist, the issue is typically logical, such as device configuration problems, timing issues, or protocol errors. The device displays these logical failures with clear diagnostic messages.

Testing Physical Layer Issues

Detailed Cable Testing with the PROFtest XL II

When the PB-Q ONE reveals low signal quality or physical anomalies, detailed cable testing becomes necessary. The PROFtest XL II cable tester provides comprehensive physical layer diagnostics to detect cable faults that cause signal degradation and network instability.

Cable Testing Parameters

Testing must be performed from both ends of the suspect segment. The PROFtest XL II measures and reports:

✓ Actual cable length, cable impedance, and baud rate verification

✓ Cable fault identification including line and shield interruptions, short circuits, and termination verification

These measurements identify specific cable problems such as breaks, crimping damage, incorrect cable types, or improper installation. The device stores all test results and can generate detailed logs via PC connection for documentation and compliance purposes.

Preventing Future Failures with Proactive Monitoring

Moving from Reactive to Predictive Maintenance

Rather than waiting for failures to occur, implementing permanent network monitoring with the PROFIBUS-INspektor® NT provides early warning of developing issues. This proactive approach allows maintenance teams to address problems during scheduled downtime rather than emergency repairs.

The INspektor® NT can function as part of a comprehensive permanent monitoring solution, continuously tracking network health and alerting operators when communication quality degrades below acceptable thresholds. This predictive maintenance strategy significantly reduces unplanned downtime and extends network component life.

Essential PROFIBUS Infrastructure Components

PROFIBUS Repeaters for Network Segmentation

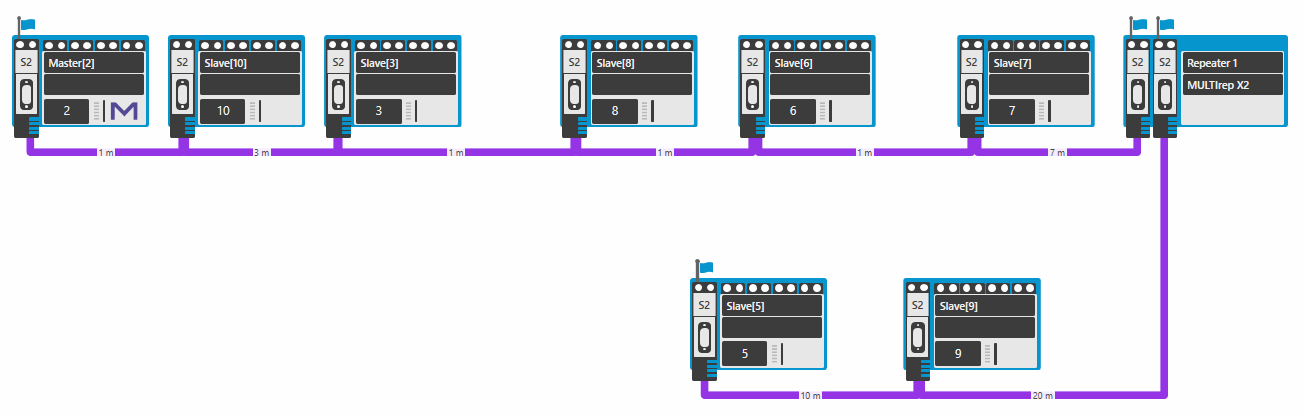

PROFIBUS network architecture requires physical measurements at the beginning and end of each network segment. The MULTIrep repeater family facilitates this by providing accessible measurement points at each channel using the PG interface on the SUB-D connectors.

These diagnostic repeaters support up to seven galvanically isolated segments, enabling robust star network topologies. The key advantage is fault isolation: problems in one segment don't affect other segments, and diagnostic LEDs quickly identify which segment is experiencing issues. This segmentation simplifies troubleshooting by limiting the scope of investigation.

Permanent Measuring Points

For network segments without accessible PG interfaces at the beginning or end, the PBMA II measuring point creates permanent diagnostic access. These measuring points should be installed during network planning to ensure accessibility for future maintenance and troubleshooting.

Complete PROFIBUS Diagnostic Solutions

InduSol's PROFIBUS diagnostic tools provide comprehensive solutions for commissioning, troubleshooting, maintenance, and acceptance testing. For organizations seeking a complete diagnostic toolkit, the PROFIBUS Diagnostic Set includes the INspektor® NT, PB-Q ONE, PROFtest XL II, and EMCheck® leakage current measuring clamp for thorough network analysis.

By following this systematic approach to PROFIBUS failure analysis, you can quickly identify problems, minimize downtime, and implement preventive measures that keep your industrial networks running reliably.

Need Help with PROFIBUS Troubleshooting?

Our team specializes in PROFIBUS network diagnostics and failure analysis. Whether you're dealing with intermittent errors or complete network failures, we can help identify and resolve the root cause.

Schedule a consultation: We'll analyze your network data and recommend the right diagnostic approach for your specific issues.

Emergency support: Experiencing unexpected downtime? We're here to help. +1 (678) 880-6910 or support@indusolamerica.com