Industrial Ethernet Switch Monitors Communication in the Logistics Center

The PROmesh Industrial Switches monitor networks and applications to ensure that the highly automated warehouse technology runs smoothly without unscheduled downtime.

PROmesh P9 for a Strong Network

The topic of Industry 4.0 poses new challenges for data communication: Short transmission times, high availability, real-time and, above all, high reliability are more important than ever. Networks must be monitored to detect signs of vulnerabilities in good time, ideally before a malfunction occurs. High-performance infrastructure components such as switches that monitor network quality while also storing data and visualizing and generating alerts play an important role in this context, for example in modern omni-channel logistics centers.

Puma, one of the world's leading brands of sports footwear, apparel and accessories, invested in a new European central warehouse, which went into operation in April 2021. Conveniently located on the A3 near Würzburg, the Geiselwind site now serves various distribution channels and handles orders from all over Europe. This is made possible by the efficient, highly automated intralogistics of the new central warehouse, which was supplied by the Austrian intralogistics specialist TGW Logistics Group (see company box below) with headquarters in Marchtrenk (Austria).

Shuttle system with high performance lifters

The centerpiece of the solution is the Stingray Shuttle system with over 700,000 storage locations (see picture below), which stores and retrieves new and returned goods on product-friendly trays fully automatically and supplies the manual picking workstations.

The total length of the energy-efficient conveyor system linking all areas is more than 21 km. 24 high-performance lifters with one or two independently movable lifting tables ensure the correct allocation of the shuttles to the individual levels of the rack in order to reach the storage locations with maximum efficiency and performance (see header picture). Like all other components of the intralogistics system in the central warehouse, the lifters also communicate with the higher-level controller via PROFINET.

This communication must be safe and reliable to ensure that the highly automated warehouse technology runs smoothly without unscheduled downtime. Even the smallest anomalies must therefore be detected so that "real" errors do not occur in the first place. This task is performed on the lifters by switches from network specialist Indu-Sol.

The PROmesh P9s (see picture beside) take care of both network and application monitoring. Depending on the number of lifting tables, two to three of these "smart managers" are now in use per lifter. Thanks to their dimensions of just 105 mm high, 49 mm wide and 122 mm deep, the switches, which are designed for DIN rail mounting, fit easily into the control cabinet of the lifters, which also had to be designed as compactly as possible.

Powerful smart managers

There were many reasons for the choice. Thomas Wimmer (see picture beside), Project Manager R&D Smart Mechatronics, names the most important ones:

PROFINET was essential for us because, for example, the camera systems on the hoists also use it to communicate. Due to the cable lengths, a special requirement for us was that leakage currents are also measured.

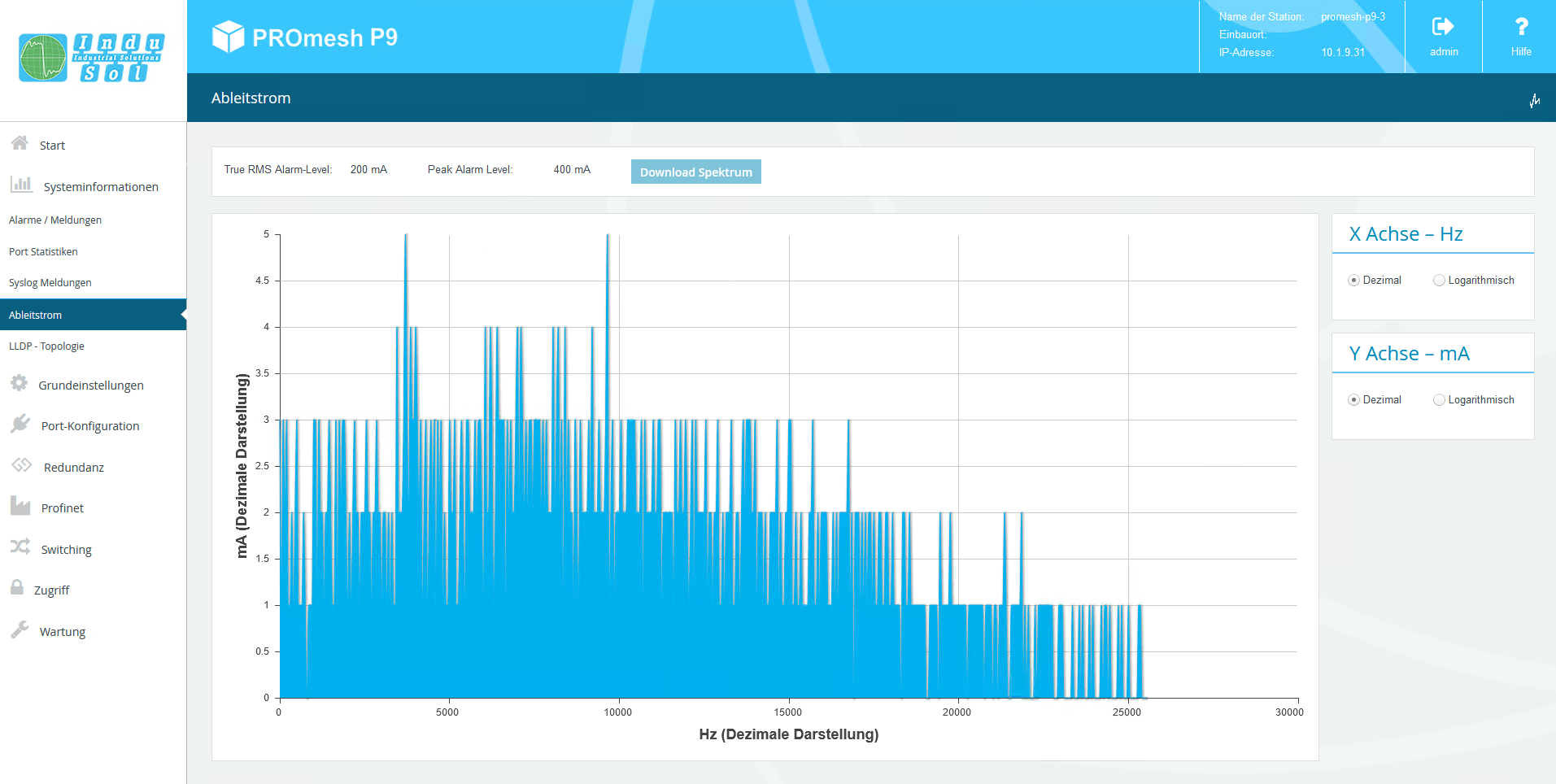

These potential equalization currents, which enter the devices via the shielding of the data lines, can cause irregularities in the data traffic. To prevent this, an integrated measuring circuit in the switch permanently monitors these currents and stores the values, including the frequency curve, if they are exceeded (see picture below).

Continuous measurement over the entire frequency spectrum (20 kHz) and recording of average values (RMS measurement) and peaks also make it possible to trace the causes of and correlations between EMC disturbances. If this leakage current exceeds predefined threshold values, this represents a danger to interference-free communication and a targeted warning is issued.

With this function, the PROmesh P9 simultaneously fulfills a recommendation by the user organization PROFIBUS & PROFINET International (PI) entitled "Functional Grounding and Shielding of PROFIBUS and PROFINET". This clearly calls for the provision of a monitoring facility to check the current shielding current level.

Equally important was the millisecond-accurate display of the network load. Here we were able to identify short-term load peaks in detail. Added to this was the wide operating temperature range of the devices. This allows us to use the same switches for projects in refrigeration areas, for example,

Thomas Wimmer continues.

But the switch has even more to offer: It satisfies the requirements of Conformance Class B, was easy to integrate into the automation environment, and meets the most stringent EMC requirements. In addition, a variety of useful management features are supported, such as IGMP snooping, VLAN, QoS, SNMP and it has four priority queues per port.

User-oriented user interface and alert management

In addition to these functions, the switch offers a user-oriented operator interface. The web interface displays the port assignment and important port status information directly on the homepage at a glance and visualizes them clearly in traffic light colors for the system operator. For example, in addition to the basic availability and neighbor detection of a port, the network load, discards and errors are recorded, permanently compared with preset trigger values and warnings are issued if necessary. Alert management via a potential-free contact, by e-mail, central SNMP query or directly to the PLC ensure timely warning of the failure. All irregularities are documented internally and recorded as a snapshot.

The clearly presented information is extremely beneficial for our maintenance and repair personnel,

adds Thomas Wimmer. Preventive maintenance measures are easy to implement and the employees also know right away what needs to be done.

The sporting goods manufacturer can focus on its core processes while TGW's on-site technicians proactively work on the maintenance and continuous improvement of the system.

Smooth commissioning

The commissioning of the switches on the lifters went smoothly.

Indu-Sol provided us with very competent support, even when we subsequently needed a new feature in the message signature to further optimize the procedure,

recalls Thomas Wimmer.

So it is no surprise that the collaboration continues. In all projects in which the high-performance lifters will be used in the future, the PROmesh P9 switches will play their part as "network managers". Perhaps the new PROmesh P10 will also come into play here; despite being the same size, it also permanently monitors the quality of the connected lines in order to make the physical wear of network lines visible.

About TGW Logistics GmbH

TGW Logistics Group is a leading international provider of intralogistics solutions. For 50 years, the Austrian specialist has been implementing automated systems for its international customers. As a system integrator, TGW takes care of the planning, production and implementation of complex logistics centers - from mechatronics and robotics to control systems and software. TGW Logistics Group has subsidiaries in Europe, China and the USA and has more than 3,800 employees worldwide. In the 2020/2021 fiscal year, the company generated total sales of 813 million euros.