PROFINET Agent - "Agent Blond" 124030300

For a quote request, please call us at +1.678.880.6910 or email info@indusolamerica.com

ⓘ Please contact us for partner and OEM pricing here.

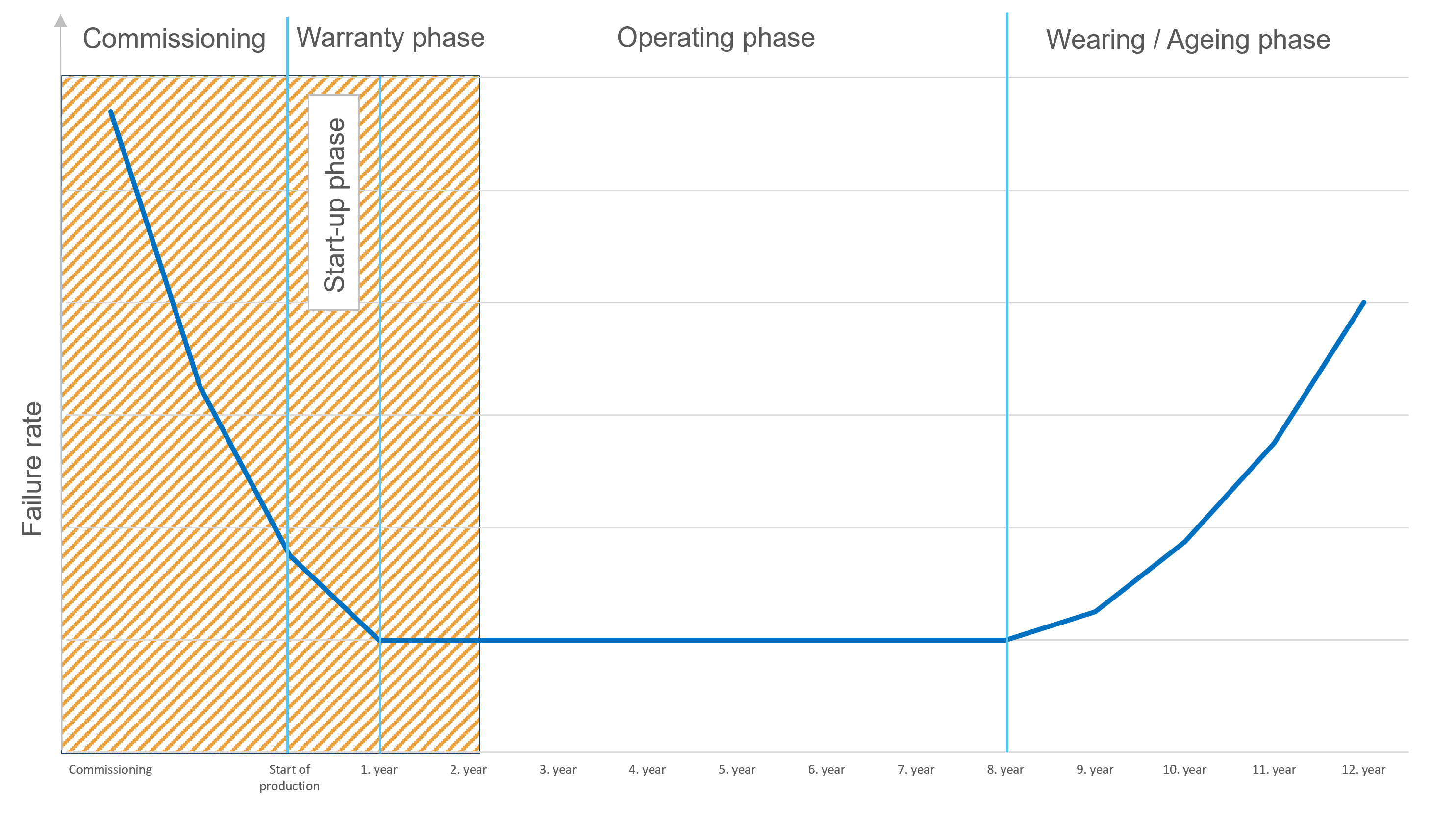

In complex machinery and plant engineering projects, efficient and timely commissioning is essential. However, in reality, disturbances often occur during commissioning due to the "bathtub curve" effect (see below). These require quick responses.

The PROFINET Agent "Agent Blond" provides structured, PLC-visible information so you can identify causes faster and bring the system to stable operation sooner. Agent Blond helps commissioning teams move from reactive troubleshooting to predictable start-up.

Bathtub effect

A high error rate at the beginning is normal and not unique to electrical, mechanical, or network systems. It is a normal and necessary phase when transitioning a machine or plant into continuous operation. It only becomes problematic when this phase drags on—because device failures reappear at different points in the network over time, causing delays and unplanned downtime.

Often the PLC reports a failed device, it gets replaced, and the cycle repeats until the true cause—such as a faulty backbone cable—is finally found.

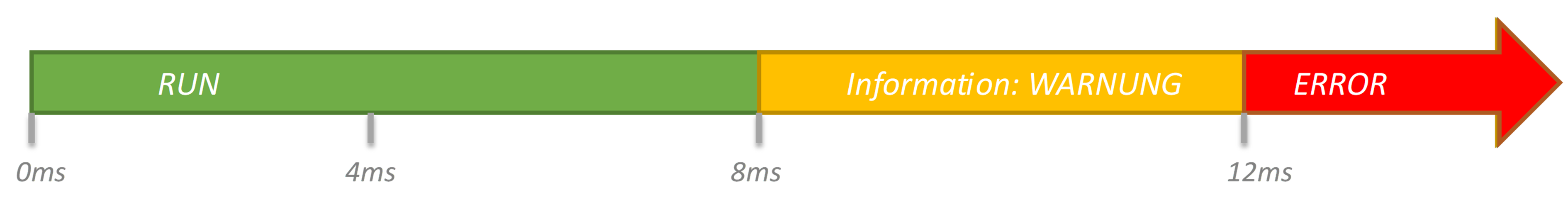

Typically the PLC diagnostic buffer shows only two states: “working” or “not working” (green or red). Using the traffic light metaphor, the valuable yellow range—information and warnings—is missing, even though parameters exist that could make it visible. If we assume there are no truly sudden, unforeseeable faults (apart from a power failure), the real task is to predict failures or at least localize and describe them earlier.

Telegram analysis cycle with PROFINET Agent “Agent Blond

What is “Agent Blond”?

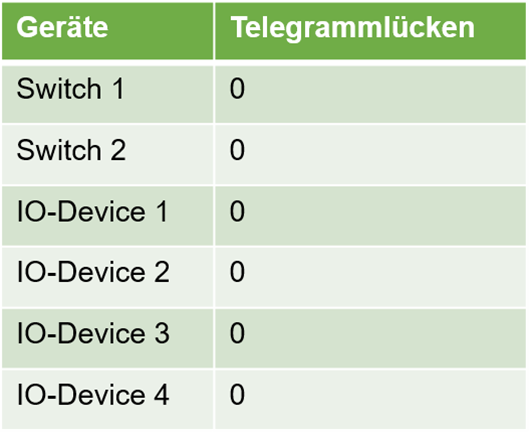

Agent Blond passively listens as a non-intrusive measurement point (TAP) to monitor PROFINET communication and reports quality indicators—such as telegram gaps—through the familiar PLC diagnostic buffer. These “yellow” notifications give the commissioning engineer actionable information as soon as the first disturbance occurs, minimizing typical troubleshooting loops.

How does it work?

Every device needs an update time (cycle) to transmit data. PROFINET adds a buffer called response monitoring time (watchdog), usually set to two or three times the update time. If transmission doesn’t succeed within this window, the system switches to a safe state and communication with that device is terminated.

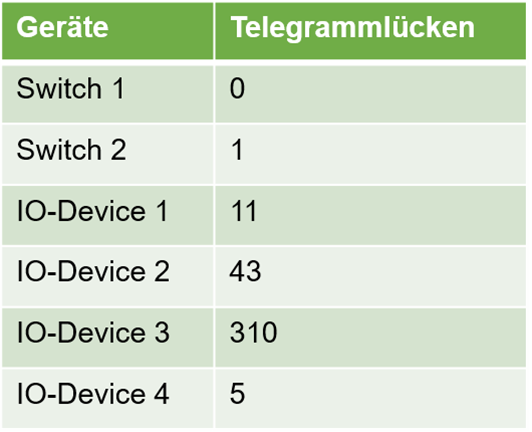

Each missed transmission leaves a telegram gap. In default PLC settings, up to three gaps are tolerated and not recorded—so early irregularities remain “invisible.” Exceeding the watchdog triggers the error state. By counting/localizing these gaps per device, you can pinpoint faulty cables, connectors, backbone segments, devices, or EMC influences, and verify fixes with before-and-after comparison.

Installation location in the PROFINET network

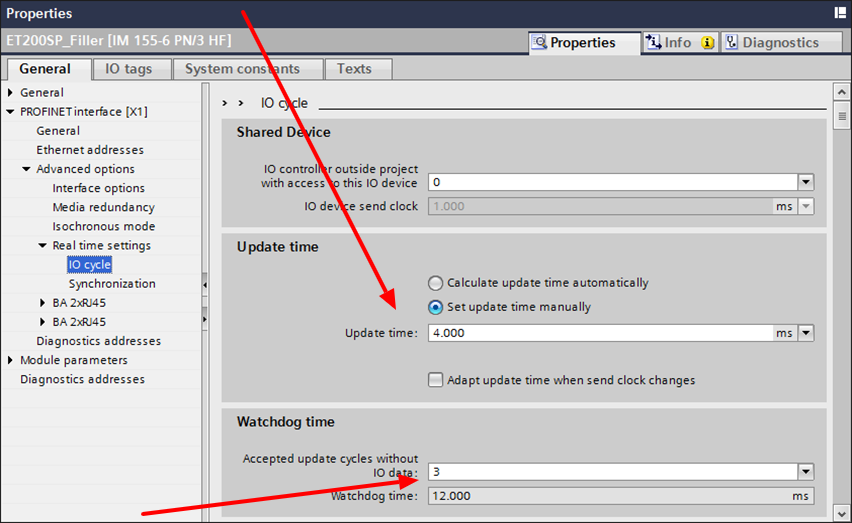

Excerpt from TIA Portal: PROFINET default setting

Update time: Defines the transmission interval of each device.

TIA Portal properties panel showing update time setting

Response monitoring time: A multiple of the update time; defines how long missing data is tolerated before switching to a safe state.

The occurrence of a telegram gap is a reliable early indicator of PROFINET data quality. Device-related messages provide a clear view of the topology, making it possible to identify the cause (faulty cable, backbone connection, connector, device) or the origin (EMC issues). Equally important: verifying success by comparing before and after.

Telegram Gaps (Before/After)

Benefits during commissioning

- Up to 50% time & cost savings: Faster fault localization and resolution reduce commissioning time and costs.

- Structured process: Move from reactive troubleshooting to proactive fault prevention.

- Long-term cost reduction: Optimize infrastructure and reduce downtime.

- Higher plant availability: Minimize unplanned outages with PLC-visible early warnings.

Ready to evaluate Agent Blond?

Talk to an engineer or get pricing today.