Monitoring

Network Monitoring and Management for Industrial Plants

Condition-focused maintenance, remote management, avoiding power failures, etc.

Flexible Monitoring Solutions for Industrial Networks

Individual. Across Networks. Scalable.

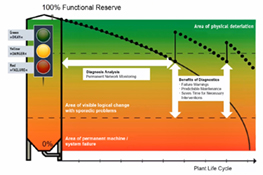

Stable and reliable operation is one of the most important priorities for any industrial plant. Most faults and malfunctions can be detected early on, provided the network has a diagnostic system (permanent networking monitoring, or PNM for short).

Monitoring solutions begin at a single analysis data collector, such as the PROFINET-INspektor® NT or a PROmesh switch with integrated diagnosis function. Any number of additional data collectors can be used depending on system type, network structure, and requirements. Since these devices were also designed for independent operation, they often come with dedicated web-based monitoring applications. This, or manual reading of long-term data stored on the device, permits detailed evaluation at any time.

Operators of complex or multiple systems can centralise and partially automate professional condition monitoring via the PROmanage® NT network monitoring software. Stay informed about critical events automatically on top of using evaluation, thorough analysis, and long-term storage of status data of your fieldbuses and industrial Ethernet networks.

Why you should switch to permanent network monitoring

Automatic condition monitoring is a part of our everyday lives, so much so that we are not consciously aware of it. One example is a cars' onboard diagnostic system. As a driver, you hardly notice the ongoing system monitoring as long as everything is running smoothly. When an error occurs, it gets recorded by the vehicle's diagnostic system that can be read, evaluated, and repaired by the technician with minimal effort. In the event of potentially critical errors, the driver is immediately alerted before the vehicle breaks down.

Would you be willing to forego your car's onboard diagnostics? Absolutely not! Then why would you go without it in your industrial system?

What is permanent network monitoring/condition monitoring?

The maintenance of your plant becomes significantly uncomplicated with the seamless recording of your network's condition. Physical and logical system values get recorded and evaluated similarly to selective (maintenance) measurements with simple measurement clamps. However, because the data is being recorded permanently, in more detail, and even simultaneously at several measuring points, maintenance staff can detect irregularities early on and correct the causes early on - the basis for cost-efficient, condition-based maintenance.

Seven advantages of using permanent network monitoring

1. Preventative, condition-based monitoring

No more unnecessary scheduled maintenance! Know precisely where anomalies are occurring and which components need servicing.

2. Correctly assess interference reserves

Efficiently avoid entering a critical disturbance range by maintaining an overview of your system's entire condition at all times.

3. Ensure network stability

Unlike random or cyclical sample measurements, permanent documentation of your network load enables you to estimate and assess the network condition.

4. All condition values at a glance

Are all physical and logical quality values complied with? How is my network doing? A quick look at your monitoring solution gives you all the answers you need.

5. Complete status data

Maintenance staff can detect every irregularity using the recorded measured values. All events of the last 12 months are documents to the minute for optimal analysis.

6. Relief through the alarm function

Stay responsive even when you are not actively tracking the network condition. As soon as an action is needed, the integrated alarm function contacts you by e-mail, SMS, OPC, etc.

7. Save time and money with remote diagnostics

In an emergency, external service technicians can get an idea of your system's condition and allow them to start on-site without delay.

shop